The coated sand casting process is mainly used for the production of complex castings such as automobile cylinder block, cylinder head, water jacket core, all kinds of pipe fittings and valve body. After decades of development, the demand for high-quality castings is increasing, based on the ordinary coated sand process, gradually developed a special coated sand core making process, and promote the rapid development of China Casting Sand, ceramic foundry sand and other special sand.

However, in the past two years, due to increased national environmental protection regulation, the production and operation of ceramic foundry sand is restricted, resulting in unstable market supply and increased costs, more and more foundries began to choose China Casting Sand as the raw material for the coated sand process, which is the inevitable trend under the environmental protection policy.

Coating sand process

The development and application of China Casting Sand

As the use of traditional silica sand coated sand system water sandwich core, broken core, sintering, sticky sand and other quality defects are prominent, the reason is that the ordinary coated sand at high temperature strength and expansion and other properties can not meet the needs of complex weak water sandwich core, and China Casting Sand can be a good solution to this problem, and in lieu of ceramic foundry sand has a great advantage.

1. Avoid sand core cracking due to expansion at high temperature, causing defects such as broken core and vein pattern

Before the core test, without increasing the purchase cost of coated sand, determine the China Casting Sand to add the proportion of 50%, other conventional performance requirements and 40% ceramic foundry coated sand the same, and two special cladding sand and ordinary cladding sand of the performance of the system testing and analysis, the results are as follows.

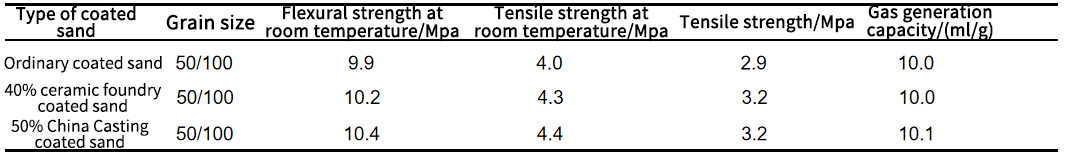

Table 1-coated sand conventional performance test results

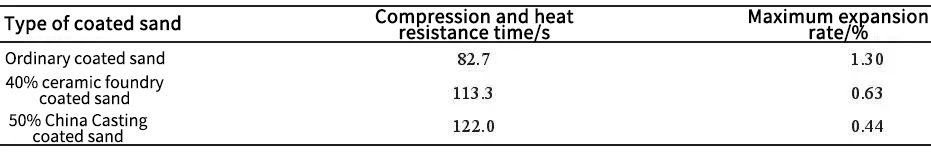

Table 2 - high temperature performance test results of the coated sand

(testing temperature 1000 ℃)

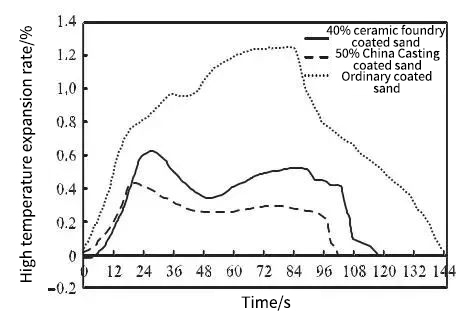

Figure 1-coated sand 1000 ℃ expansion curve

Comprehensive data look like.

1)Conventional performance, 50% China Casting Sand coated sand and 40% ceramic foundry coated sand are basically the same, and are higher than the ordinary coated sand, mainly because the special coated sand grain shape is better than silica sand, which is conducive to improve the strength of the coated sand.

2)1000 ℃ high temperature compressive performance test, with constant pressure on the standard specimen pressure until the specimen collapse, compressive heat resistance time results for: 50% China Casting coated sand > 40% ceramic foundry coated sand > ordinary coated sand, China Casting Sand high temperature compressive performance outstanding performance.

3)High temperature expansion, with the extension of the test time, the expansion rate shows a trend of first growth and then decline. The common coated sand reached the maximum value of 1.3% in 90 seconds, 40% ceramic foundry coated sand reached the maximum value of 0.63% in 25 seconds, and 50% China Casting coated sand reached the maximum value of 0.44% in 20 seconds. Compared with ordinary coated sand and ceramic foundry sand, the expansion performance of China Casting Sand is better, which can effectively avoid the defects such as broken core and vein pattern caused by the expansion and cracking of sand core under high temperature.

2. Less tendency of sand core curing and delamination

The root cause of sand core curing delamination of coated sand is that the bottom core sand settles during the curing process of sand core, and then detaches from the upper curing shell layer. The density of ceramic foundry sand is greater than that of China Casting Sand, and the tendency of settling is large and fast, resulting in the delamination of ceramic foundry coated sand curing more serious than that of China Casting coated sand.

As can be seen from Figure 2, under the same equipment and parameters, with the same location of the section of the sand core made of two types of coated sand, there is a significant curing delamination phenomenon in the sand core of ceramic foundry coated sand, China Casting coated sand core almost no delamination.

Figure 2 - Curing of coated sand cores

(left: China Casting coated sand, right: ceramic foundry coated sand)

With the widespread application of coated sand casting process and the surge of demand for high-precision casting parts, China Casting Sand, with the advantages of low cost, environmental protection and stable performance, has become the choice of more and more casting enterprises, providing strong support for the rapid development of high-quality castings!