Cold core box process, mainly used for cylinder block, cylinder head, intake and exhaust pipe and other engine castings. In the past casting production, quartz sand was mainly used to make sand cores, but due to the complex shape of some sand cores and small local cross-sectional area, the cores made with quartz sand are not easy to shoot solid, easy to fracture, and the produced castings have defects such as vein pattern, sticky sand and porosity.

In order to help customers improve the yield of castings, China Casting Sand, ceramic foundry sand and other artificial casting sand came into being. They have the characteristics of high refractoriness, low thermal expansion, low thermal conductivity, etc. In practical application, they can significantly improve casting defects and contribute to the improvement of casting dimensional accuracy and surface and internal cavity quality.

China Casting Sand cold core box process

However, due to the high energy consumption, poor environment and low recycling rate in the production process of ceramic foundry sand, China Casting Sand has become the first choice of more and more large and medium-sized engine casting enterprises due to the advantages of low cost, environmental protection and high recycling rate in the context of increasingly strict environmental protection policies.

The development and application of China Casting Sandcold core box process

Application design

Mixed with 50/100 mesh recycled sand, in order to achieve good particle size gradation effect, China Casting Sand particle size sieve number is 40/70 mesh, in view of the adverse effect of the original sand fines content on the strength of the sand core, limit the content value of 140 mesh and below in the sand.

Core making

Core making was done by mixing China Casting Sand with recycled sand at a mass ratio of 1:1, and the cold core box resin addition was 0.8% each for a single component, and the data were compared with the ceramic foundry sand process under the same conditions.

Sand core tensile strength test

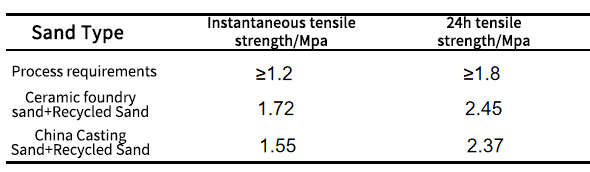

Table 1 Tensile strength of cold core box sand

From the data.

Under the current resin addition amount, the tensile strength of China Casting Sandis slightly lower than that of ceramic foundry sand, but all of them meet the process requirement standard.

In the process of core making, the filling and demoulding properties are good, and the core shot sand is tight; after the casting is cleared, the inner cavity quality is comparable to that of ceramic foundry sand process, and there is no sticky sand phenomenon. After more than half a year of verification, the product has no abnormal defects, which proves the stability and reliability of China Casting Sand cold core box process.

China Casting Sand practical application effect

From a comprehensive point of view, in the casting cold core box process, China Casting Sand can solve the problems arising from quartz sand core making, reduce the defects of engine castings and improve the quality of castings, and because of the advantages of small stacking density, low price and environmental protection, the production of the same sand core, the dosage is less than that of ceramic foundry sand, which effectively helps customers to reduce manufacturing costs and ensure stable supply and considerable economic benefits to customers under the environmental protection policy!