In line with the requirements of precision casting production process on the use of sand, more and more foundry enterprises realize the importance of low-carbon sustainable development of foundry sand in the production process, which is not only in line with the national concept of green development, but also directly related to the stability of the foundry material supply.

However, for foundry sand manufacturers, this is undoubtedly a huge challenge, which requires overcoming many difficulties in technology, process and cost.

China Casting Sand - ZhongAng New Material Series

As a new material technology company advocating the business concept of "more economical, more environmental protection, more quality", we have successfully developed China Casting Sand, an environmentally friendly, low-cost sintered ceramic sand, after years of research and development.

It not only has the characteristics of high refractoriness, low thermal expansion and high sphericity, but also has comparable use effect compared with the ceramic foundry sand in the market; it also has the advantage of low density and low price, which is beneficial to reduce the production cost of enterprises in the practical application with less dosage and low cost.

At present, the company has developed three major China Casting Sand series products, including CC-1, CC-2 and CC-3, for the specific requirements of different sand casting processes, and customers can choose according to the actual production needs.

Performance and application of China Casting Sand

China Casting Sand has been recognized by many famous casting companies at home and abroad from the very beginning, which has a great relationship with its performance.

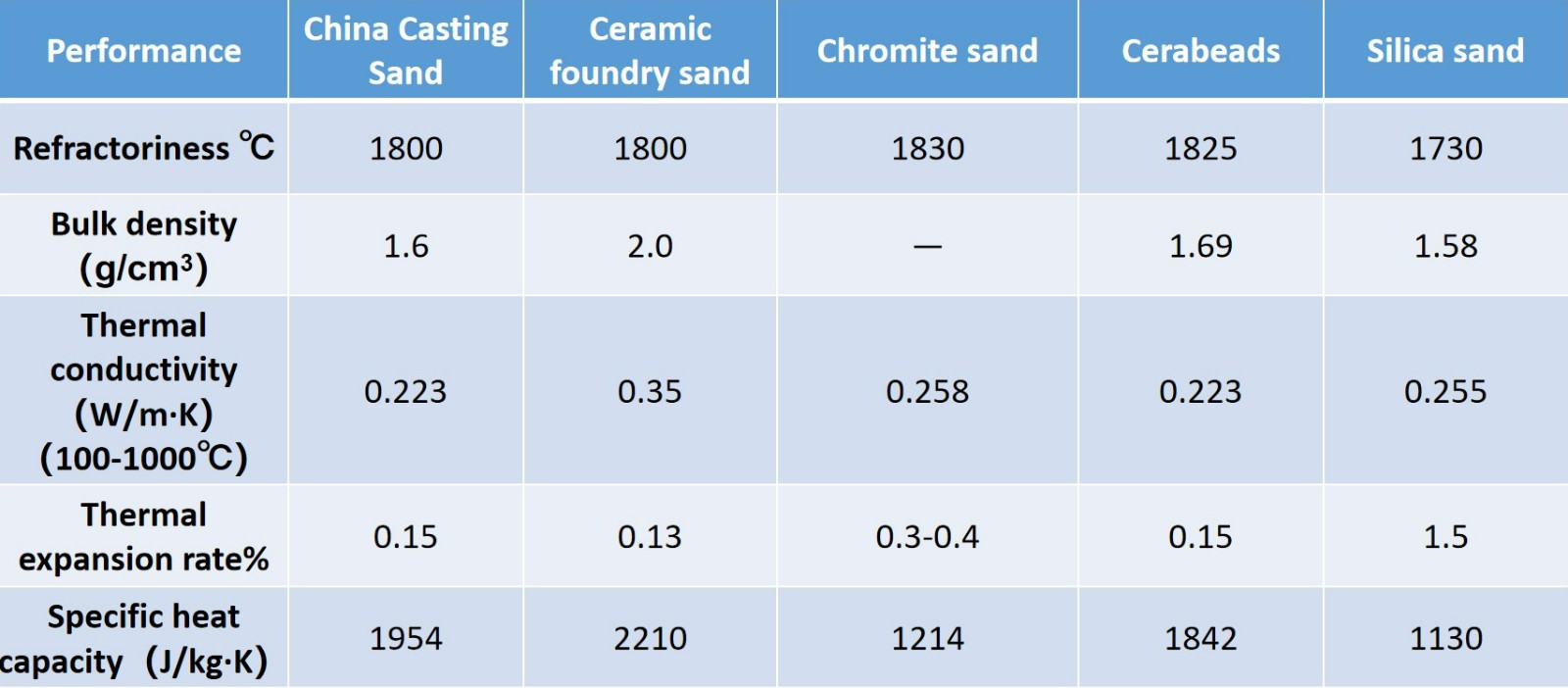

Table 1-Comparison of the performance of each casting sand

From the data in Table 1.

1. All these casting sands have high refractoriness, which can effectively reduce the casting sticky sand and easy to clear sand after use.

2. China Casting Sand stacking density is lower than that of ceramic foundry sand and Cerabeads, so the same sand core, using China Casting Sand core making, the weight of the sand core is smaller.

3. China Casting Sand has similar thermal conductivity, thermal expansion rate and refractoriness with ceramic foundry sand, and has the advantages of lower price, high production and production yield, high recovery rate and low energy consumption, so it is an ideal material to replace ceramic foundry sand.

At this stage, China Casting Sand has been widely used in different casting fields such as gasoline and diesel engine parts (cylinder block, cylinder head, water jacket core, oil channel core, turbine volute, etc.), wind power casting, engineering machinery casting, hydraulic casting, etc.