Foundry industry is a large consumption of resources and energy consumption of the industry, easy to cause pollution to the environment, in the past two years, with the national environmental protection policy tends to tighten, the national awareness of environmental protection, the foundry industry is facing transformation and upgrading, environmental protection, green, sustainable development has become the trend.

The main solid waste of sand casting production is waste sand, a large amount of waste sand is not only a waste of resources, but also cause great harm to the surrounding environment of the foundry. At present, the promotion and application of old sand regeneration technology, so that the status quo of waste sand old sand has been significantly improved, including China Casting Sand regeneration advantages are obvious, highly recognized by the foundry enterprises.

China Casting Sand regeneration utilization

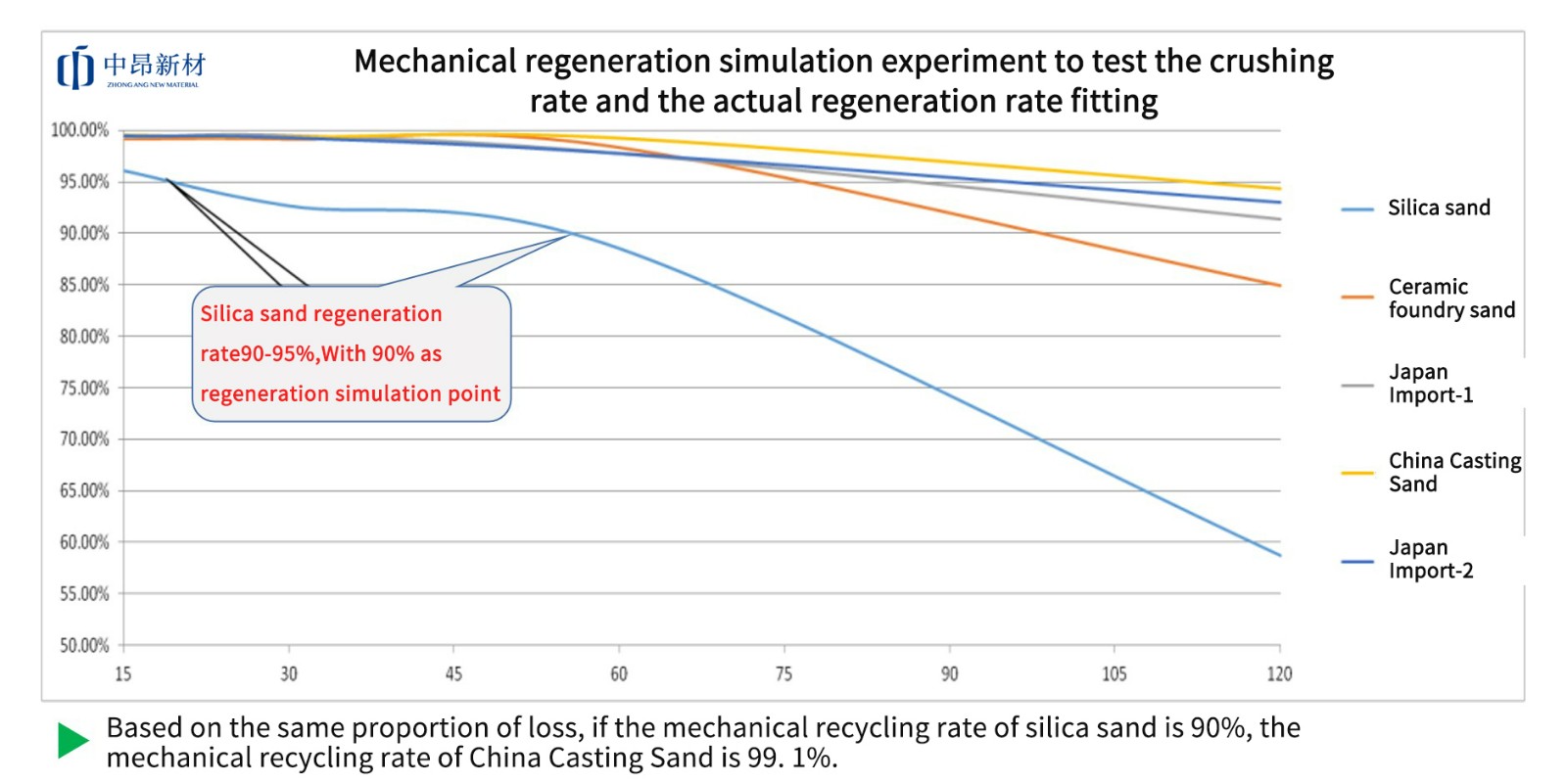

1.China Casting Sand regeneration rate and before and after comparison

Due to the irregular shape of silica sand, repeated use will not only affect the permeability of the sand, and because of its low strength, regeneration will produce a lot of waste. In contrast, China Casting Sand is nearly spherical in shape, and after repeated regeneration, the surface is more polished and better spherical, with no reduction in strength, less waste and high utilization rate.

The Mohs hardness of silica sand is about 6~7, which is easily worn out by mechanical equipment when it is ground mechanically, while the Mohs hardness of China Casting Sand is 8~9, which has a smaller relative wear rate.

2.China Casting Sand regeneration performance

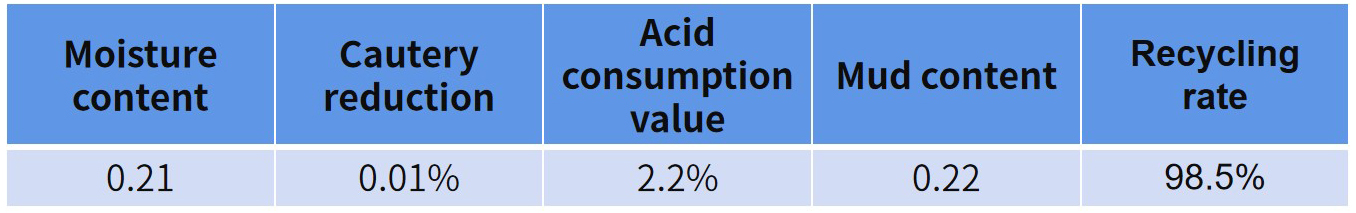

A foundry will China Casting Sand regeneration treatment, testing its scorch reduction, mud content, acid consumption value and other indicators (see the figure below). Conclusion: China Casting Sand regenerated with low burn loss, compared with new sand, acid consumption value is almost the same, and when put into use, reduce the amount of new sand additions and solid waste emissions.

In conclusion, the regeneration of China Casting Sand has obvious advantages, because of its good collapse, reducing the workload of vibration screening; because of its high strength, reducing the amount of dust generated and the amount of new sand added, significantly reducing solid waste emissions, can be repeatedly recycled, more suitable for regeneration and recycling.