Resin sand process is a molding and core making process by adding a certain amount of acidic curing agent to furan resin sand, which is self-hardening under normal temperature conditions, with the advantages of less defective castings, low scrap rate, high dimensional accuracy, smooth surface and clear contour, etc. It is widely used in small and medium batch cast iron and steel production line and core making process.

Since the raw sand has a great influence on the performance of furan resin sand, the amount of binder, and the surface quality of castings, and silica sand cannot meet the conditions of producing high-quality castings, meanwhile, CC sintered ceramic sand has been widely promoted for its excellent performance in the application of this process.

Application of China Casting Sand furan resin casting process

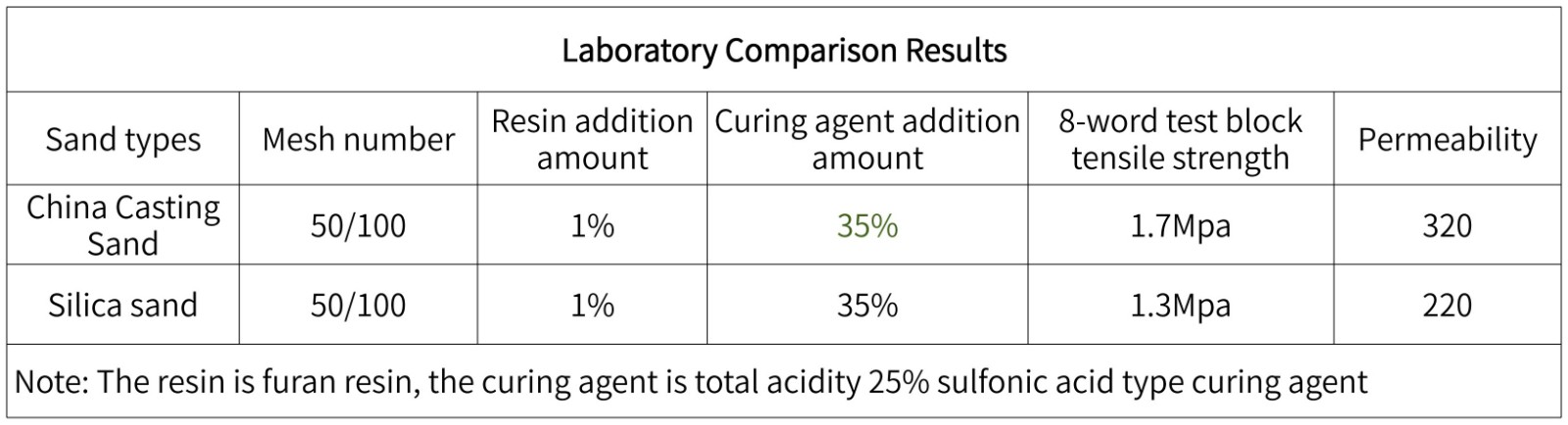

Experimental preparation

Take 50/100 mesh China Casting Sand and silica sand, resin and curing agent are added at 1% and 35% respectively, and test the tensile strength and permeability of 8-word test block.

Experimental results

1. China Casting Sand has high refractoriness (≥1800℃), high sphericity, high strength and excellent air permeability under the same liquid material addition.

2. sand trapping defects and sand strength are related to each other, sand strength will be improved significantly, and the strength of China Casting Sand is 20-30% higher than that of silica sand under the same resin addition, which is conducive to solving sand trapping in castings.

3. Resin sand process requires low acid consumption value of the original sand to reduce the adverse effects on the curing process and casting quality, while the acid consumption value of China Casting Sand is 1.0, which is the most ideal sand for casting at present.

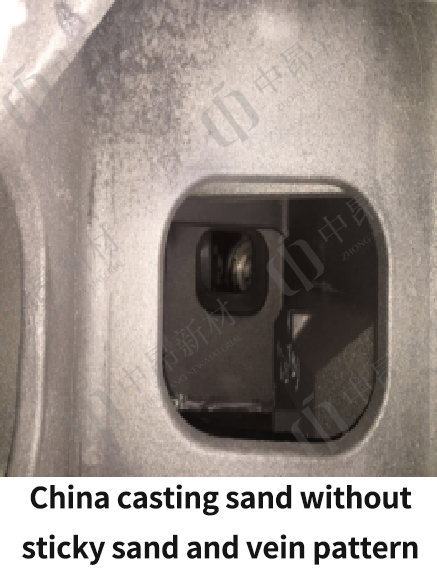

Case show

Casting weight: 10 tons

Silica sand to iron ratio: 5:1

China Casting Sand to iron ratio: 3:1

After this foundry used China Casting Sand, it effectively solved the sand sticking and veining of castings, reduced the difficulty and cost of later cleaning; reduced the sand-iron ratio, and the sand required to produce 1 ton of castings was reduced from 5 tons to 3 tons.

Advantages of China Casting Sand recycling

The old sand can be well recycled and regenerated is a major advantage of furan resin sand, how to control the quality of regenerated sand is the key to produce high quality castings.

1. Due to the irregular shape of silica sand grains, the air permeability of the sand will be affected after repeated use, while the surface of China Casting Sand is smooth and better sphericity after regeneration, which does not affect the air permeability of the sand.

2. China Casting Sand has good collapsibility, which can reduce the workload of vibration screening, and because of its high strength, the repeated recycling rate is as high as 99.1%, which can significantly reduce the solid waste emission.