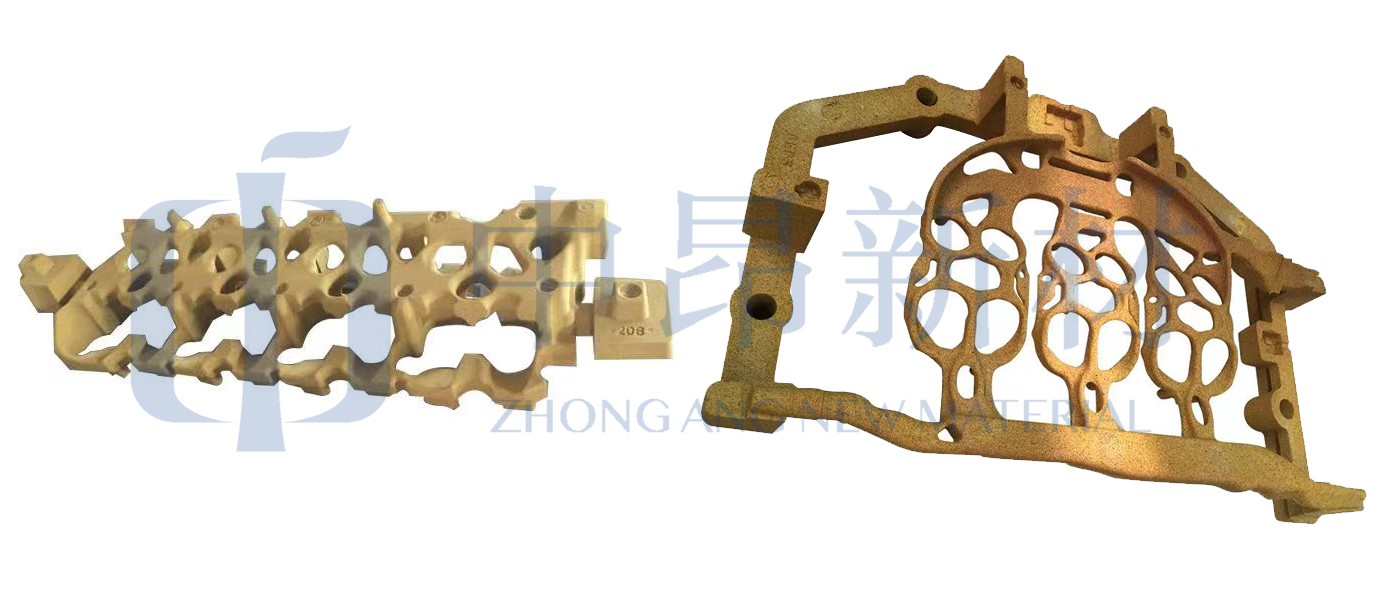

Engine block and cylinder head castings are one of the most difficult and important aspects of engine production, and their quality plays a key role in engine power and fuel consumption. As the automotive engine block and cylinder head are typical thin-walled complex parts, sand cores, high dimensional accuracy, the production of castings can not have pores, cracks and other defects, waterway oil channels also need to be tested by the airtightness, can not have leakage.

In the past, quartz sand core, there is not easy to shoot solid, easy to fracture problems, in the penetration of high temperature iron, very easy to form sinter, can not meet the requirements of high quality castings. The development and application of China Casting Sand solves the above problems and obtains high quality sand cores while effectively avoiding defects in castings.

Core making with China Casting Sand

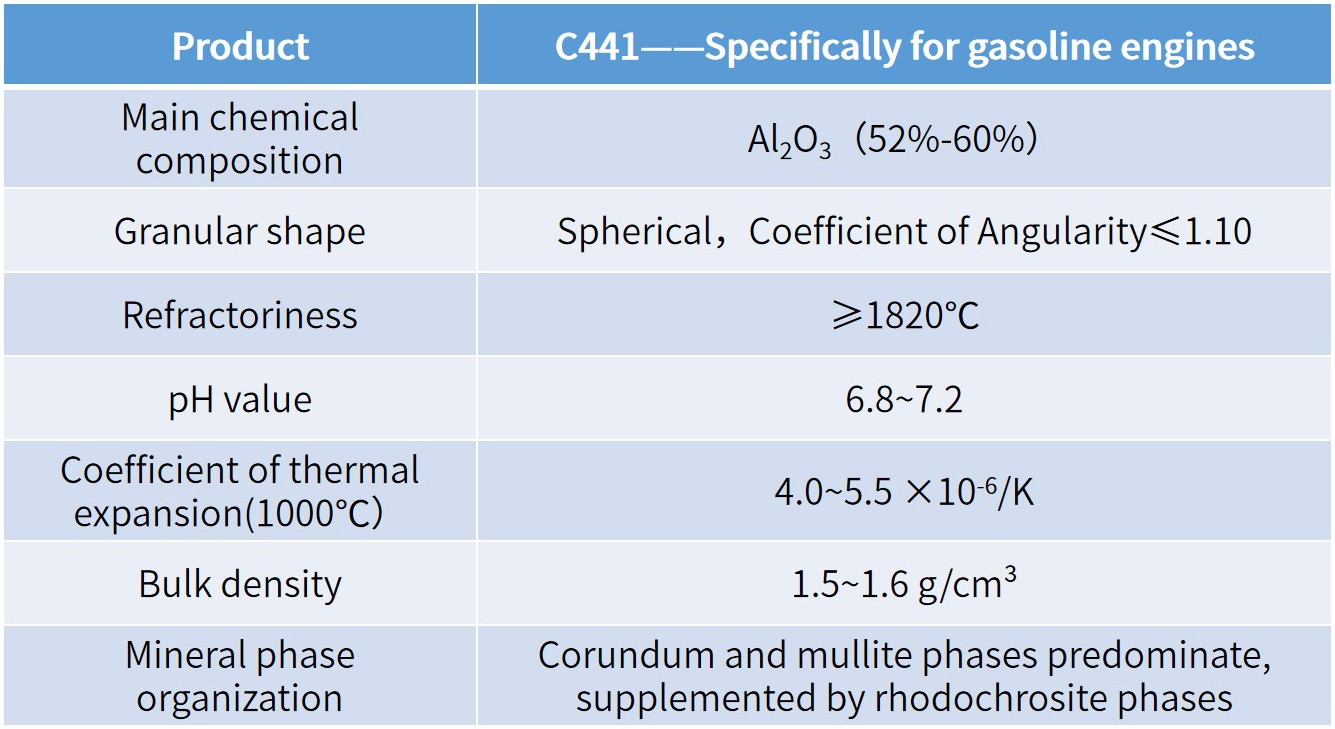

China Casting Sand performance index

Due to the excellent performance of China Casting Sand, it has obvious advantageous features compared with other foundry sands, as follows.

1. comparable or slightly higher refractoriness compared with chromite sand and ceramic foundry sand, better high temperature compressive and heat resistance time, and much lower probability of sticky sand.

2. expansion rate is better than magnesium sand, chrome sand, silica sand, and similar to ceramic foundry sand, which is conducive to improving the accuracy of casting size and surface, internal cavity quality.

3. The Mohs hardness reaches 8.2, which achieves the ultra-low crushing rate during mechanical grinding in the regeneration process.

4. PH value is neutral, suitable for various acid and alkaline binders (water glass, Piper resin, furan resin, phenolic resin, etc.), without changing the existing binder used by customers.

5. The specific gravity of stacking is smaller than that of ceramic foundry sand and chromite sand, which can greatly reduce the sand-iron ratio and lower the casting cost; when mixed with silica sand, the shot sand can be filled densely; during the curing process of sand core, there is no curing delamination, and the tendency of sand core curing and deshelling is smaller.

China Casting Sand applied to cylinder block

In practical application, the use of C441 ceramic sand core making has solved the problems of sand core deformation, sintering, veining and other defects, and the quality of cylinder block and cylinder head has been significantly improved, and the cleanliness of engine cavity has been greatly improved. At the same time, comparing with ceramic foundry sand, the dosage is less and the cost performance is high, which can bring considerable economic benefits to the enterprise in a comprehensive view.