China is a large casting country, according to the data in 2020, casting production accounted for 49.24% of the world. But behind the high production, the drawback is the serious pollution of the environment, therefore, the state has repeatedly issued documents requiring strict control of high pollution, high energy consumption industry production capacity, and the introduction of supply-side reform and environmental governance-related policies.

As a foundry molding material manufacturer, since its establishment in 2014, ZhongAng New Material has taken "more economical, more environmentally friendly and better quality" as its business philosophy, and is committed to research and development of foundry environmental protection special sand, not only to provide stable and efficient service experience for foundry enterprises, but also to the cause of environmental protection, to solve the poor environment of foundry sand production, energy consumption High energy consumption and other series of problems.

At present, it has 100% replaced molten ceramic sand in cold core box, Coated sand, 3D printing, Resin sand, Lost Foam Casting and other process fields.

China Casting Sand environmental protection development

1. High efficiency and environmental protection of production process, high rate of finished products

China Casting Sand adopts advanced production process, which is inspected strictly and grinded in homogenization and then batch charged by numerical control to be granulated under great force to get accurate particle size distribution after balls sintered in the high temperature and then mixed according to grade.The whole process is pollution-free, low energy consumption, low noise, and does not produce flocculent high alumina cotton and other by-products, reducing the pollution to the environment.

Meanwhile, the raw material utilization rate of China Casting Sand is high, the finished product rate is high, and the production process reduces the waste of materials, which has a positive effect on environmental protection.

2. High recycling rate, can be repeatedly recycled

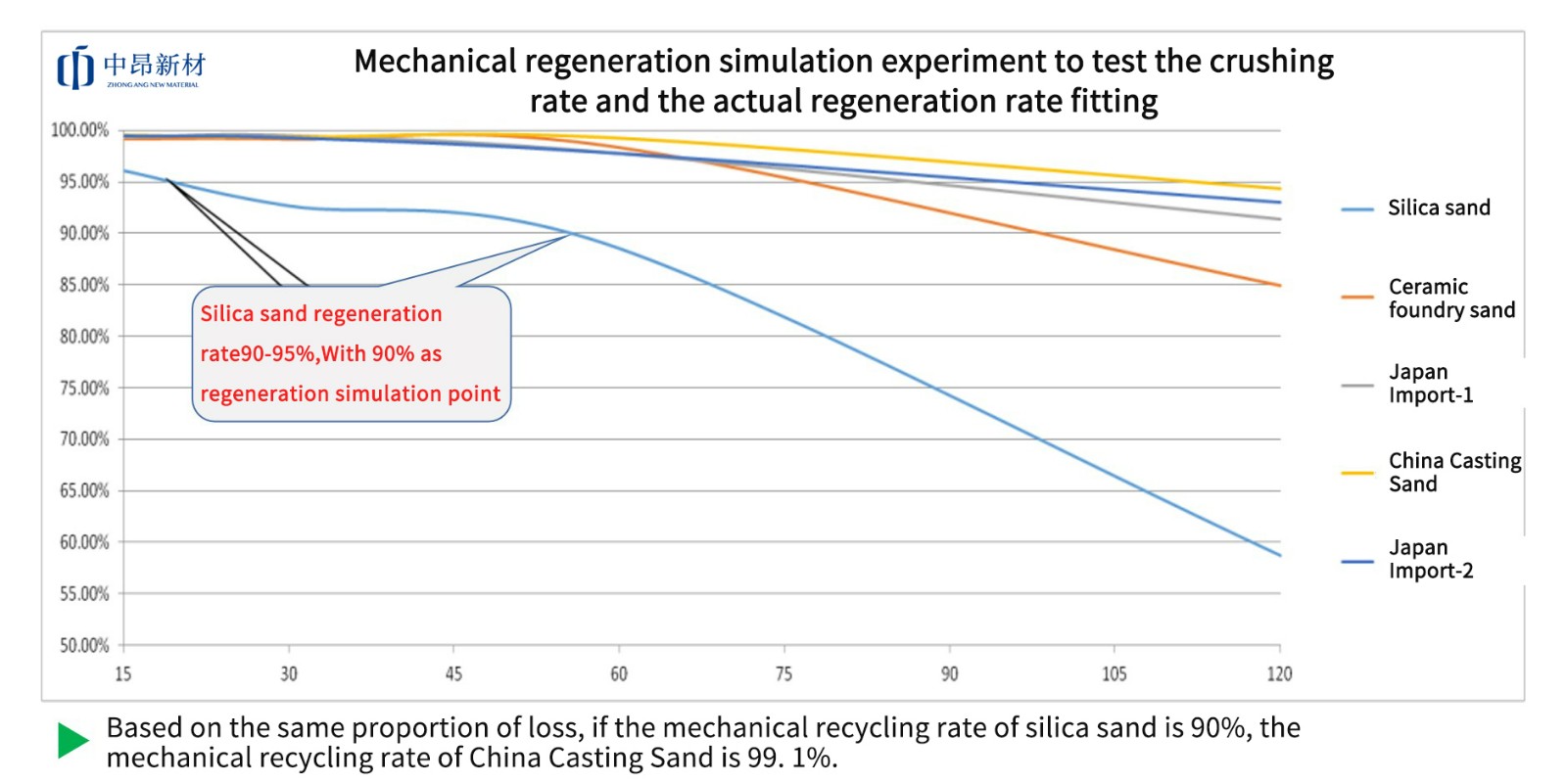

The most serious environmental pollution from foundry production is solid waste and air pollution, and the solid waste of sand casting is mostly waste sand, to alleviate the emission of waste sand, the old sand regeneration technology is rapidly promoted. Therefore, the recycling rate of old sand is an important reference indicator to measure whether the foundry sand is environmentally friendly.

The China Casting Sand has a rounded particle shape, Mohs hardness of 8-9, high strength and low wear rate, and can be repeatedly recycled and used with a regeneration rate of 99.1%, which significantly reduces solid waste emissions.

3. Drafting and developing group standards to promote the healthy development of sintered ceramic sand

The development and application of China Casting Sand is highly recognized by enterprises and experts in the industry, which opens up new opportunities for the development of special sand environmental protection.

To this end, as the pioneer of China Casting Sand, we fully understand the current situation of the development of sintered ceramic sand for casting at home and abroad, and seek the views of casting manufacturers and industry experts and scholars, drafted and formulated the "sintered ceramic sand for casting" and other group standards, certified by the China Foundry Association issued to promote the healthy and orderly development of sintered ceramic sand for casting preparation industry, driving more colleagues to practice " green casting" development path.

Green water and green mountains, not overnight work, but to protect the environment, everyone needs to participate.ZhongAng New Material continues to pay attention to green development, empowering products with innovation and contributing to the sustainable future of the foundry industry.