As we all know, the surface quality of the casting is closely related to the molding material, and the original sand grain size and particle size distribution directly affects the process performance of the sand, which in turn affects the quality of the casting.

If the original sand grain size is coarse, the metal liquid will easily penetrate into the pores of the sand, causing the casting to stick to the sand, and the surface quality of the casting is low. On the contrary, the finer grain size of the original sand can produce castings with higher surface quality, but the amount of binder added is higher, which also reduces the permeability of the sand mold or core, and the castings are prone to pore-like defects.

As one of the special casting sands, China Casting Sand has excellent characteristics such as high refractoriness, low thermal expansion, high sphericity, low density and high wear resistance, and is widely used in various sand casting processes. In the actual production, in order to meet the process requirements of different customers, China Casting Sand has achieved wide particle size distribution and reasonable grading, and can be produced according to the customer's particle size distribution requirements.

At present, China Casting Sand is mainly used in the process fields of cold core box, Coated sand, 3D printing, Resin sand, Lost Foam Casting, water glass, etc. The particle size distribution of China Casting Sand used by customers is roughly as follows for reference only.

(1) Cold core box process

China Casting Sand AFS between 40-65 is more commonly used, 4 sieve or 5 sieve distribution, concentration rate ≥ 85%. The filling and demoulding properties are good during use, and the core shot sand is tight, plus the stacking density is close to that of silica sand, and there is no segregation when mixed with silica sand, and the casting quality is high.

(2) Coated sand

China Casting Sand AFS is mainly concentrated between 50-110, 4 sieve or 5 sieve distribution, concentration rate ≥ 85%. China Casting Sand is used for foundry cladding sand, high temperature compressive property, high temperature expansion is better than treasure bead sand, effectively avoid sand core in high temperature due to expansion and cracking caused by broken core, vein pattern and other defects, and at the same time has the advantage of small tendency of sand core curing decrustation.

(3) 3D printing process

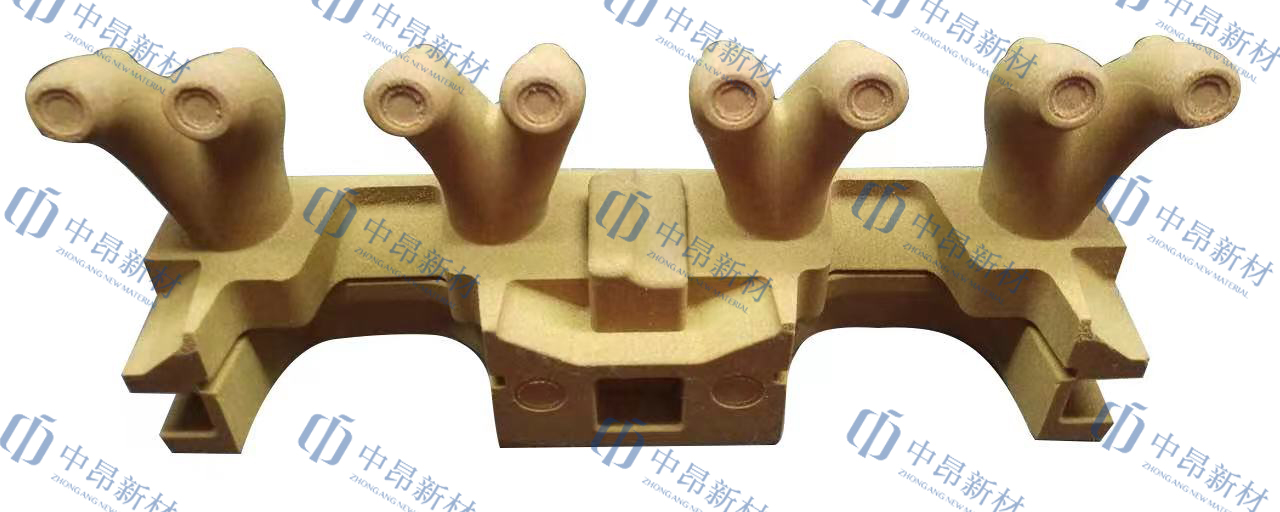

CC vitrified sand AFS between 70-100 is more commonly used, concentration rate ≥ 85%. Used for 3D printing casting, solve the problem of casting prone to sand sticking and vein defects, easy to clear sand later, applied to diesel cylinder heads and larger machine tool castings with ideal results.

(4) Resin sand process

China Casting Sand AFS between 30-65, 4 sieve or 5 sieve distribution, concentration rate ≥ 80%. In practice, the use of China Casting Sand sand sand strength, good permeability, conducive to solving the casting sand trapping and other defects, coupled with the sand acid consumption value is low, reducing the curing process and casting quality caused by the adverse effects.

(5) Lost Foam Casting

Usually use 10/20 mesh, 20/30 mesh China Casting Sand, high permeability, plus CC vitrified sand crushing rate is low, high recycling rate, to ensure the recovery rate after pouring, recycling of new sand replenishment is small.