The Lost Foam Casting casting process is a globally recognized near-net molding process that can reduce costs through integrated and integrated casting design and light weight design. In the early stage of Lost Foam Casting application, the original sand is mainly used quartz sand, but with the rapid development of Lost Foam Casting process, quartz sand is restricted by the refractoriness, thermal expansion rate and other performance limitations, the application defects are more and more obvious, mainly manifested as serious sand sticking on the casting surface, low casting surface accuracy, sand cleaning difficulties.

The China Casting Sand, which is independently developed by ZhongAng New Material, is an ideal raw sand for Lost Foam Casting because of its high refractoriness, low thermal expansion, high sphericity and high recovery rate, which can effectively solve the problem of sand sticking on castings and other defects.

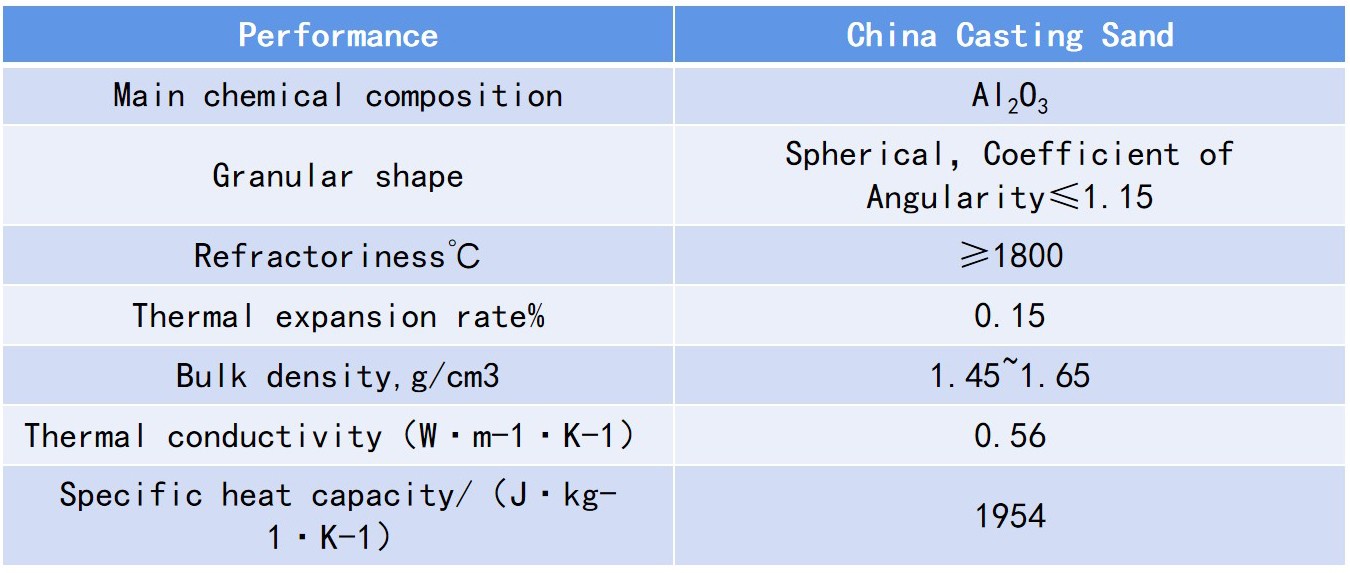

Performance of China Casting Sand

China Casting Sand is inspected strictly and grinded in homogenization and then batch charged by numerical control to be granulated under great force to get accurate particle size distribution after balls sintered in the high temperature and then mixed according to grade.

Table 1 - China Casting Sand physical properties

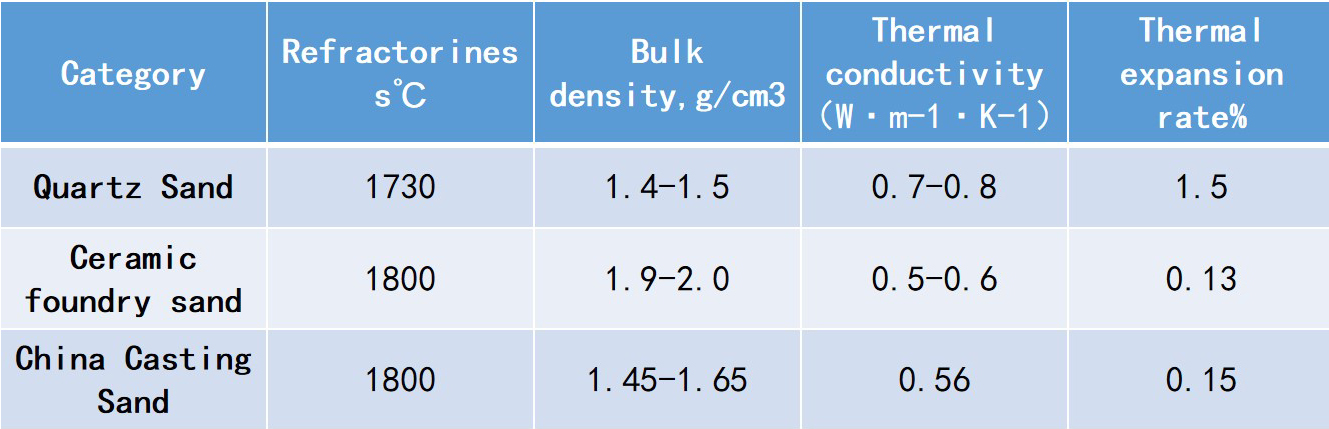

Performance comparison of several common Lost Foam Casting casting sands

At present, the commonly used sands for Lost Foam Casting include quartz sand, ceramic foundry sand and China Casting Sand, their performance comparison is as follows.

1. Quartz sand refractoriness is lower than ceramic foundry sand, China Casting Sand, casting local (such as: holes, slots and other parts) sticky sand serious, cleaning difficulties, in the production of large cast steel parts, sticky sand situation is more serious.

2. The thermal expansion rate of quartz sand is high, 10 times higher than that of China Casting Sand, and at different temperatures, quartz sand undergoes multiple crystal phase changes, with large volume changes.

3. Quartz sand is easy to be broken and pulverized, and the amount of dust in the workshop is high, which cannot meet the requirements of environmental protection, resulting in poor operating environment for workers and low number of reusable cycles.

4. Compared with ceramic foundry sand, China Casting Sand has three other advantages as follows.

China Casting Sand particles have high mechanical strength, inner and outer porcelain solid, no hollow phenomenon, low crushing rate, high recycling rate.

In the application of Lost Foam Casting, due to the influence of production process, the crushing rate of ceramic foundry sand is higher than China Casting Sand, and the number of recycling is lower than China Casting Sand, so the amount of new sand replenishment using China Casting Sand is less than ceramic foundry sand.

Comparison of China Casting Sand (left) and ceramic foundry sand (right) after 480h mechanical grinding

②Low cost. Since China Casting Sand is less dense than ceramic foundry sand, the usage quantity is less, so the overall usage cost is more advantageous than ceramic foundry sand and more cost-effective.

③More environmental friendly. Influenced by the policy, the market price of ceramic foundry sand has increased and the supply is unstable due to the restriction of poor production environment and high energy consumption, while the production process of China Casting Sand is more environmental friendly, high yield rate and low energy consumption, so it has become the preferred material for many casting enterprises.

Application of China Casting Sand in the lost foam casting process

Summary

China Casting Sand is used in the Lost Foam Casting process, which can effectively reduce casting defects such as sand sticking to castings and help enterprises to reduce production costs.